Chattanooga (WTVC) — There are only 7 shopping days left before Christmas, and every year we go back into our archives with some local gifts that could find their way under YOUR tree. From getting in the Christmas spirit with local spirits, to protecting your teens on the internet, here are our "Made in Our Hometown" 12 gifts of Christmas.

Don't fret if the skirt under your tree is shy a few gifts. The Made in Our Hometown Elf has you covered with products made not far from your front door.

1. Sockwell socks- made in an East Ridge mill, these compression socks keep athletes, nurses and those flying the friendly skies on their feet. (visit Sockwell's website)

2. Reunion Yarn breaks down discarded sweaters to make knitters yarn new again, offering a monthly subscription service for the crafter in your clan. (visit Reunion's website)

3. Appalachian Bee uses their home-grown beeswax for natural, soap, lip balm and other soothing sweetness. (visit Appalachian Bee's website)

4. Chattanooga-made Hoff & Pepper can spark the palate of anyone on your present-picking list. (visit Hoff & Pepper's website)

5. Hot Chocolatier specializes in 20 different flavors of hot cocoa confections-- but the icing on the top the cake-- is their homemade marshmallows, complete with a last-minute touch. (visit the Hot Chocolatier's website)

6. The Torch- Perhaps one of Chattanooga's most successful start-ups of the season took Kickstarter by storm. It now offers parent-friendly routers to control what your elves are surfing around the Christmas dinner table. (visit The Torch's website)

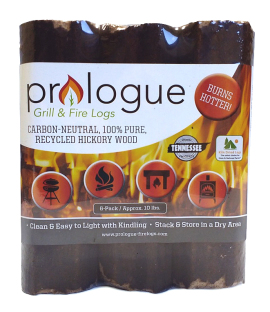

7. Prologue's green Fire Logs, made in Whitwell, can easily fill your fireplace or smoker, creating the perfect puff of recycled smoke. (visit Prologue's website)

8. Chattanooga's Chef and his Wife can fill up your table, with homemade food, frozen or chilled. (visit the Chef and his Wife's website)

9. Chattanooga Whiskey hopes customers take away a samplilng of one of their first batches of barrel-aged spirits, made in our hometown. (visit Chattanooga Whiskey's website)

10. The Debarge Vineyards in Lafayette grows gapes on their vines to sell as stocking stuffers at their Southside store. (Visit DeBarge's website)

11. Alko-Hauler: a local sewing start-up that creates custom koozies in their Lakesite basement. (Visit Alko-Hauler's website)

12. Strum to Strut takes used guitar strings and fashions unique jewelry-- that might make the perfect melody for your Christmas Carol. (visit Strum 2 Strut's website)